Barcode Scanning: Boosting Security in Pharmaceutical Packaging

The Role of Barcode Scanning In the pharmaceutical industry, ensuring the safety and integrity of products is paramount. One of the most effective ways to enhance security in pharmaceutical packaging is through barcode scanning. This technology not only streamlines operations but also safeguards against counterfeit products, ensuring that consumers receive genuine medicines. With the increasing…

Table of Contents

The Role of Barcode Scanning

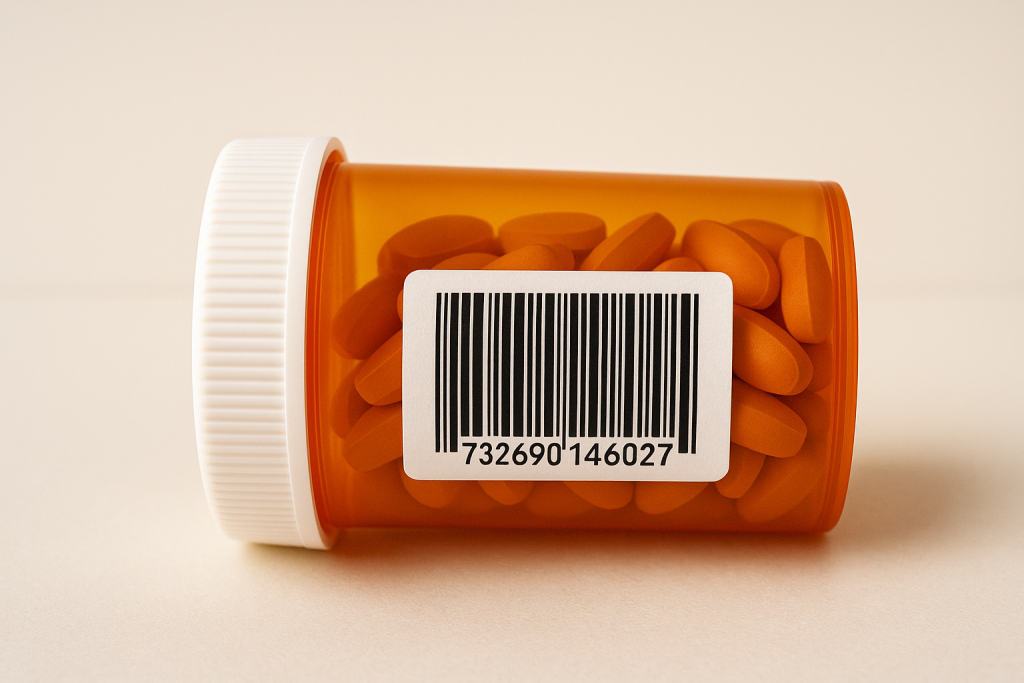

In the pharmaceutical industry, ensuring the safety and integrity of products is paramount. One of the most effective ways to enhance security in pharmaceutical packaging is through barcode scanning. This technology not only streamlines operations but also safeguards against counterfeit products, ensuring that consumers receive genuine medicines. With the increasing sophistication of counterfeiters, the need for robust security measures in pharmaceutical packaging has never been more critical. This blog will explore how barcodes enhances security in pharmaceutical packaging, delves into its various benefits, and discusses its impact on the overall safety of pharmaceutical products.

The Importance of Security in Pharmaceutical Packaging

Pharmaceutical packaging must meet stringent regulations to protect consumers and maintain product integrity. Security measures are critical to prevent counterfeit drugs, which pose serious health risks. According to the World Health Organization (WHO), approximately 10% of medicines in low- and middle-income countries are estimated to be counterfeit. This alarming statistic underscores the importance of security in pharmaceutical packaging. Barcode scanning serves as a vital tool in addressing these challenges, as it provides a reliable method for tracking and verifying products.

Understanding Barcode Technology

Before diving deeper into the benefits of barcode scanning, it’s essential to understand how barcode technology works. A barcode is a visual representation of data that can be scanned and interpreted by a machine. It typically consists of parallel lines of varying widths (1D barcodes) or a grid-like pattern (2D barcodes). The data encoded in a barcode can include various information such as product identification numbers, batch numbers, expiration dates, and more.

When a barcode is scanned using a barcode reader, the scanner decodes the information and sends it to a connected system for processing. This process allows for quick and accurate retrieval of product information, which is essential in maintaining the security and integrity of pharmaceutical packaging.

How Barcode Scanning Works

This scanning involves the use of specialized scanners that read printed barcodes on pharmaceutical packages. These barcodes contain essential information about the product, including:

- Product Identification: Each pharmaceutical product has a unique identifier that distinguishes it from others. This helps in tracking the product throughout the supply chain.

- Batch Numbers: Batch numbers indicate the specific production run of a product. This information is crucial for traceability in case of recalls or quality control issues.

- Expiration Dates: Expiration dates are vital for ensuring that consumers receive safe and effective products. Barcode scanning allows for easy tracking of expiration dates, ensuring that expired products are not distributed.

Benefits in Pharmaceutical Packaging

- Counterfeit Prevention One of the most significant advantages of barcode scanning is its ability to prevent counterfeit drugs from entering the supply chain. By verifying the authenticity of products, barcode scanning effectively reduces the risk of counterfeit drugs reaching consumers, which is critical for maintaining public health and safety. According to the U.S. Food and Drug Administration (FDA), the implementation of barcode scanning has been instrumental in combating counterfeit drugs and ensuring that patients receive safe and effective medications.

- Improved Traceability Barcode scanning enhances traceability throughout the supply chain. If a product issue arises, companies can quickly trace the product’s history and identify the source of the problem. This level of traceability is essential for compliance with regulatory requirements and for implementing effective recall strategies. In the event of a quality issue, having a robust traceability system in place allows companies to act swiftly to mitigate potential risks.

- Regulatory Compliance Pharmaceutical companies must adhere to strict regulations regarding packaging and labeling. Barcode scanning helps ensure compliance by providing accurate data that can be easily accessed and verified. Regulatory agencies, such as the FDA and the European Medicines Agency (EMA), have established guidelines that require pharmaceutical companies to implement systems for tracking and tracing products. Barcode scanning is an essential component of these systems, as it allows for real-time monitoring and verification of products throughout the supply chain.

- Efficiency and Cost Savings Implementing barcode scanning can significantly reduce manual errors and streamline operations. This efficiency translates into cost savings for pharmaceutical companies as they spend less time on inventory management and more on production. With barcode scanning, companies can quickly and accurately process shipments, manage inventory levels, and ensure that products are delivered to customers on time. This increased efficiency not only reduces labor costs but also enhances customer satisfaction by ensuring timely delivery of products.

- Enhanced Inventory Management Barcode systems enable real-time inventory tracking, ensuring that pharmaceutical companies have the right products on hand and reducing the risk of stockouts or overstocking. By automating inventory management processes, companies can gain better visibility into their stock levels and make informed decisions about reordering products. This level of inventory control is crucial in the pharmaceutical industry, where maintaining optimal stock levels is essential for meeting customer demand while minimizing waste.

The Role of Miniature Folding Inc. in Security Solutions

At Miniature Folding Inc., we understand the critical nature of pharmaceutical packaging. Our specialized packaging solutions incorporate advanced security features, including barcode scanning technology, to enhance the safety and integrity of your products. With our commitment to quality, you can trust that your pharmaceutical packaging meets the highest standards.

Key Features of Our Barcode Scanning Solutions

- Customization: We offer customizable packaging solutions tailored to your specific needs, ensuring that your products are both secure and visually appealing.

- Integration: Our barcode scanning technology can be seamlessly integrated into your existing packaging processes, enhancing efficiency without disrupting operations.

- Support: Our experienced team is dedicated to providing ongoing support and training to ensure that your staff can effectively utilize barcode scanning technology.

Challenges and Considerations

While barcode scanning offers numerous benefits, there are also challenges and considerations that pharmaceutical companies must address when implementing this technology. These include:

- Initial Investment: Implementing a barcode scanning system requires an initial investment in hardware, software, and training. Companies must weigh the long-term benefits against the upfront costs to determine the feasibility of adopting this technology.

- System Integration: Integrating barcode scanning technology into existing systems can be complex. Companies must ensure that their current software and processes are compatible with the new technology to avoid disruptions.

- Employee Training: Proper training is essential for the successful implementation of barcode scanning. Employees must be familiar with the technology and understand how to use it effectively to maximize its benefits.

- Data Management: Managing the data collected through barcode scanning can be challenging. Companies must have robust data management systems in place to ensure that the information is accurate, secure, and easily accessible.

Future Trends in Barcode Scanning for Pharmaceuticals

As technology continues to evolve, so too will barcode scanning in the pharmaceutical industry. Here are some emerging trends to watch:

- 2D Barcodes and QR Codes: The adoption of 2D barcodes and QR codes is on the rise in the pharmaceutical industry. These codes can store more information than traditional 1D barcodes, allowing for enhanced product tracking and consumer engagement.

- Integration with Blockchain: The integration of barcode scanning with blockchain technology is gaining traction. Blockchain can provide an immutable record of product movements, further enhancing traceability and security.

- Mobile Scanning Solutions: The use of mobile devices for barcode scanning is becoming more widespread. Mobile scanners offer flexibility and convenience, allowing employees to scan products on the go and access real-time data.

- Artificial Intelligence (AI): AI technologies are being integrated into barcode scanning systems to enhance data analysis and decision-making processes. AI can help identify patterns in product usage, predict demand, and optimize inventory management.

Conclusion

In conclusion, barcode scanning is a vital component of security in pharmaceutical packaging. It enhances product traceability, prevents counterfeiting, ensures regulatory compliance, and improves inventory management. For pharmaceutical companies looking to bolster their security measures, implementing barcode scanning technology is an essential step.

As the industry evolves, embracing new technologies and trends will be crucial in maintaining the integrity and safety of pharmaceutical products. By partnering with experts like Miniature Folding Inc., companies can ensure that their packaging solutions meet the highest standards of quality and security.

For more information on how we can assist you with secure pharmaceutical packaging solutions, visit Miniature Folding Inc. or contact us today for a free estimate!

You Might Find Interesting:

- For more on the benefits of barcode technology in pharmaceuticals, visit Pharmaceutical Technology.

- Learn about regulatory compliance and security in pharmaceutical packaging at FDA.gov.

Related Insights

Keep Exploring Sustainable Packaging Trends

Read more

Read moreWhat Makes a Folding Insert High Quality? Key Features to Look For

High Quality Folding Inserts In the competitive landscape of packaging, folding inserts or folding sheets

Read more

Read moreThe Ultimate Showdown: How Barcode Scanning Tags Stack Up Against QR Codes for Product Tracking

In the rapidly evolving landscape of inventory management and product tracking, businesses are increasingly relying

Read more

Read moreEnhancing Patient Safety: How Folded Inserts Outperform Digital Information Leaflets

In the healthcare sector, effective communication is crucial, especially when it comes to patient safety.