Embracing the Legacy: The Evolution and Importance of Legacy Pharmaceutical Packaging

The pharmaceutical industry is one of the most regulated sectors globally, with packaging playing a crucial role in ensuring product safety, efficacy, and compliance. While innovation is at the forefront of modern pharmaceutical packaging, understanding and appreciating the role of legacy pharmaceutical packaging is equally important. This article delves into the evolution of legacy pharmaceutical…

The pharmaceutical industry is one of the most regulated sectors globally, with packaging playing a crucial role in ensuring product safety, efficacy, and compliance. While innovation is at the forefront of modern pharmaceutical packaging, understanding and appreciating the role of legacy pharmaceutical packaging is equally important. This article delves into the evolution of legacy pharmaceutical packaging and its continued significance in today’s market.

Understanding Legacy Pharmaceutical Packaging

Legacy pharmaceutical packaging refers to traditional packaging methods and designs that have been used historically in the industry. These methods have been the foundation of pharmaceutical packaging and have evolved over time to incorporate new technologies and materials while maintaining core principles of safety, reliability, and compliance.

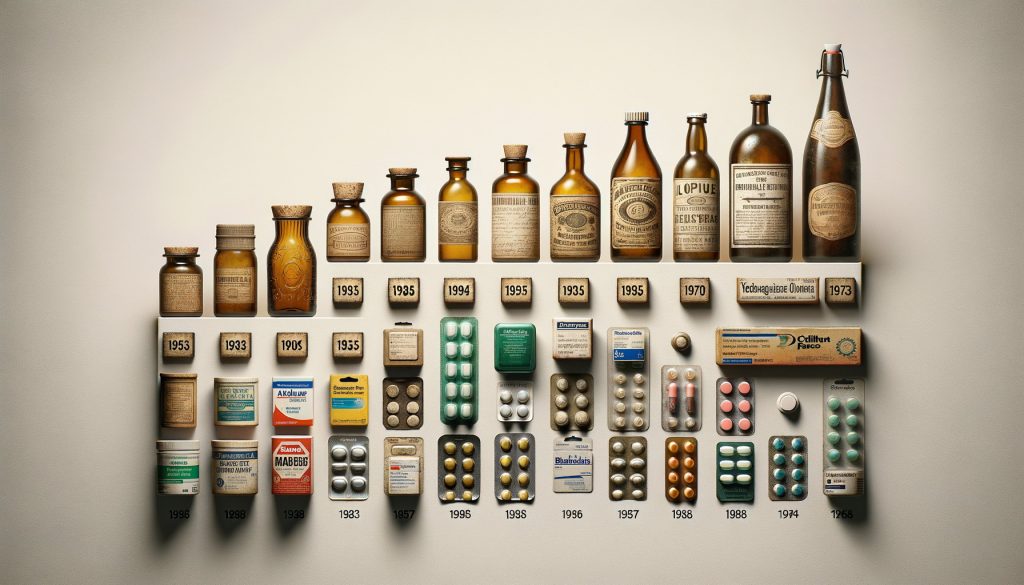

The Evolution of Legacy Packaging

Materials and Technology

Early pharmaceutical packaging relied heavily on materials like glass and metal, which provided excellent protection against contamination and degradation. Over time, advancements in materials science introduced plastics, which offered greater flexibility and cost-effectiveness. Despite these changes, many legacy aspects, such as using glass for certain medications, remain due to their proven effectiveness.

Design and Functionality

Legacy packaging designs were primarily focused on protecting the product and providing essential information. Over the decades, the design has evolved to include child-resistant features, tamper-evident seals, and user-friendly designs. These innovations have been integrated into legacy packaging methods, ensuring they meet modern safety standards.

Regulatory Compliance

Legacy pharmaceutical packaging has set the benchmark for compliance within the industry. As regulations have become more stringent, legacy packaging has adapted by incorporating necessary information directly onto the packaging, such as dosage instructions, expiration dates, and safety warnings, ensuring products remain compliant with evolving guidelines.

The Continued Importance of Legacy Packaging

Proven Reliability

One of the main reasons legacy packaging continues to be used is its proven track record of reliability. These packaging methods have been tested over time, providing a level of trust and assurance to both manufacturers and consumers.

Consumer Familiarity

Consumers often prefer packaging that they are familiar with, especially when it comes to medications. Legacy pharmaceutical packaging offers a sense of familiarity and trust, which is crucial in a sector where consumer confidence is paramount.

Cost-Effectiveness

While innovation can lead to new and improved packaging solutions, legacy methods often remain more cost-effective. The infrastructure for producing these types of packaging is well-established, reducing production costs and time.

Integration with Modern Innovations

Legacy packaging does not exist in isolation. Many modern innovations, such as smart packaging technologies and eco-friendly materials, are being integrated into legacy packaging designs. This hybrid approach allows manufacturers to benefit from the reliability of legacy methods while embracing the advantages of new technologies.

The Future of Legacy Pharmaceutical Packaging

As the pharmaceutical industry continues to evolve, legacy packaging will remain a vital component. Manufacturers are tasked with balancing tradition and innovation, ensuring that packaging not only meets current standards but also anticipates future needs. By integrating modern technologies and sustainable practices, legacy pharmaceutical packaging will continue to play a crucial role in the industry’s future.

Innovative and Reliable Solutions

If you’re looking for reliable and innovative pharmaceutical packaging solutions, Miniature Folding can help you navigate the balance between legacy and modern methods. Contact us today to discuss how we can tailor our packaging services to meet your specific needs while maintaining the quality and compliance your products require. Visit our website for more information and to schedule a consultation with our experts.

Related Insights

Keep Exploring Sustainable Packaging Trends

Read more

Read moreWhat Makes a Folding Insert High Quality? Key Features to Look For

High Quality Folding Inserts In the competitive landscape of packaging, folding inserts or folding sheets

Read more

Read moreThe Ultimate Showdown: How Barcode Scanning Tags Stack Up Against QR Codes for Product Tracking

In the rapidly evolving landscape of inventory management and product tracking, businesses are increasingly relying

Read more

Read moreEnhancing Patient Safety: How Folded Inserts Outperform Digital Information Leaflets

In the healthcare sector, effective communication is crucial, especially when it comes to patient safety.